How-To Select the Right Buff & Compound

To select the right buff and compound for your polishing project, it must be taken into consideration that different metals have varying characteristics. It is essential that the correct compound and buff are used together to achieve the best results and desired finish. Please see below for details regarding usage. To see Josco’s full range of polishing products, please click here.

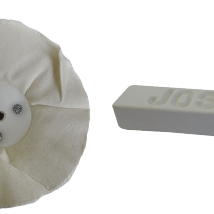

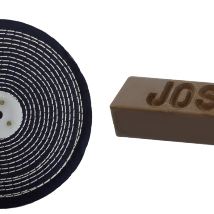

SS Compound & Loose Leaf Calico Buff

The combination of a Josco or Brumby SS Compound and a Loose Leaf Calico Buff are ideal for use when polishing aluminium and aluminium alloys. It is ideal for achieving a high quality finish.

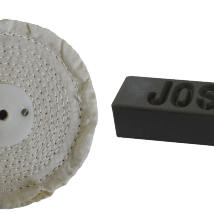

SSX Compound & Loose Leaf Calico Buff

Using a SSX Compound with a Loose Leaf Calico Buff is ideal for achieving a high gloss finish on copper, brass and stainless steel surfaces.

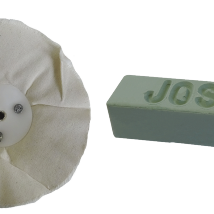

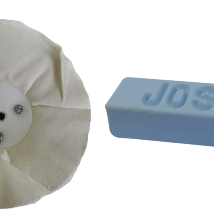

Multishine Compound & Loose Leaf Calico Buff

Multishine Compounds and Loose Leaf Calico Buffs are generally used in combination to achieve a high gloss finish on plastics and die-cast articles. Die-cast metals consist mostly of non-ferrous metals including zinc, copper and aluminium.

Tripoli Compound & Stitched Rag Buff

Tripoli is a cutting compound for general purpose cutting work on copper, aluminium and most metals. It achieves the best results when used with a Stitched Rag Buff. Cutting refers to removing light scratch marks, and it is suggested to follow up with a polishing combination after to refine the finish.

Fastcut Compound & Sisal Buff

For cutting back light scratch marks on copper, brass and stainless steel prior to polishing, it is best to combine the use of a Fastcut Compound with a Sisal Buff.